ONE OF A KIND!

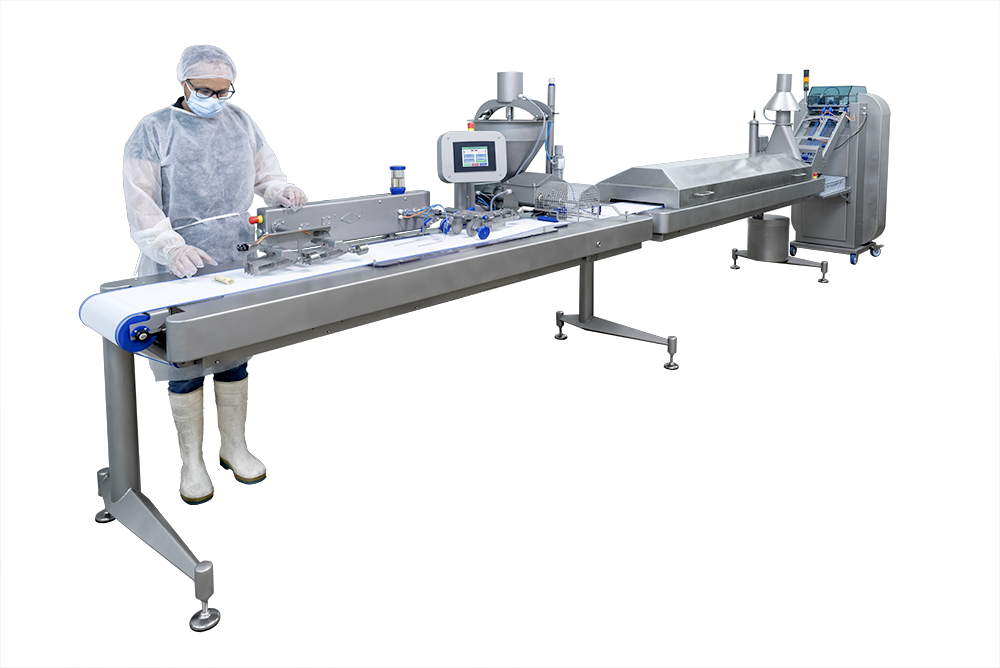

Automatic Vietnamese Spring Roll Production Line

Automatic Vietnamese Spring Roll Production Line

Introducing the latest version of our famous automatic spring roll machine. It is fully automated, capable of producing up to 2000 units per hour with just one operator.

Several years of research were required to develop this unique machine in the world.

Today, more than 82 machines are in operation, equipping numerous production workshops.

RICE PAPER

The Bretinov production line is designed to create spring rolls from traditional Vietnamese rice paper. Our machine is the only one in the world capable of folding and rolling spring rolls 100% automatically without altering the original recipe, using dry rice paper.

ENERGY SAVING

The Bretinov rice paper softener was developed with the aim of minimizing energy losses. Unlike older generations of softeners, which were energy-intensive, Bretinov concentrates the necessary power as close as possible to the rice paper to deliver the required amount of steam for softening. The overall power consumption during operation does not exceed 8 kW. This is a patented machine.

DESTACKER

Located at the beginning of the line, the destacker is fully automated. The rice paper sheets are picked up one by one by a suction cup, which places them between two belts to transport them to the softener. It safely destacks the rice paper sheets in a confined area sheltered from room humidity.

A transparent cover allows the operator to check the destacker's proper functioning. Loading the rice paper sheets can be done without stopping production. Once loaded, the destacker has an hour of production autonomy.

SOFTENER

The key step in the Vietnamese spring roll manufacturing process is the precise and uniform softening of the rice paper sheets. The water spray input is adjusted to the tenth of a gram to achieve perfect rolling and folding.

The softener is equipped with its own boiler. Steam production under pressure, directly under the rice paper sheet, prevents heat loss and saves energy.

Steam is recovered at the softener's entrance to reduce humidity in the production room.

TABLE-TOP FILLER

Several years of development were required to develop our deposit head. It respects your filling and does not crush the ingredients.

This new, miniaturized version accurately deposits calibrated doses of filling onto the softened rice paper sheet.

A continuous screw system allows precise control of the deposition head's flow rate. Interchangeable exit nozzles allow for filling diameter calibration.

Easy to clean, this filler allows for recipe variations, switching from pork to chicken, chicken to vegetarian in minutes.

TOUCHSCREEN

The touchscreen integrated into the machine's controller allows the line operator to manage all production parameters with just a few clicks.

AUTOMATIC FOLDING MODULE

The Folding and Rolling module enables complete automation of the line. A system of blowing nozzles ensures a clean and precise fold, avoiding any risk of rice paper sticking. The spring roll is then rolled before being transferred to the fryer.

It increases production capacity and produces perfectly calibrated spring rolls.

This is a patented module.

CAPACITY

Produce approximately 2000 pieces per hour in automatic mode.

SYMMETRICAL OPTION

A line operator can manage 2 lines simultaneously. Bretinov offers the symmetrical version of its spring roll line for optimal working ergonomics.